BERKENHOFF DAHMEN

Bare wire / Brass wire

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K160 | 8 kg | 2 | 500 / 900 MPa | 0,20 / 0,25 / 0,30 |

| K200 | 16 kg | 1 | 500 / 900 MPa | 0,25 / 0,30 |

| K250 | 25 kg | 1 | 500 / 900 MPa | 0,25 |

| K355 | 45 kg | 1 | 500 / 900 MPa | 0,25 / 0,30 |

| P5 | 5 kg | 4 | 500 / 900 MPa | 0,20 / 0,25 |

| P10 | 10 kg | 2 | 500 / 900 MPa | 0,25 / 0,30 |

| P15 | 20 kg | 1 | 500 / 900 MPa | 0,25 / 0,30 |

megacut® pro TWO – The new second generation brass wire for Japanese machines

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K160 | 8 kg | 2 | 1000 MPa | 0,20 / 0,25 / 0,30 |

| K200 | 16 kg | 1 | 1000 MPa | 0,25 / 0,30 |

| K250 | 25 kg | 1 | 1000 MPa | 0,25 |

| K355 | 45 kg | 1 | 1000 MPa | 0,25 / 0,30 |

| P5 | 5 kg | 4 | 1000 MPa | 0,20 / 0,25 |

| P10 | 10 kg | 2 | 1000 MPa | 0,25 / 0,30 |

| P15 | 20 kg | 1 | 1000 MPa | 0,25 / 0,30 |

BOLINE BRASS – MS-EDM wire, made by bedra

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K160 | 8 kg | 2 | 500 / 1000 MPa | 0,20 / 0,25 / 0,30 |

| K200 | 16 kg | 1 | 500 / 1000 MPa | 0,20 / 0,25 / 0,30 |

| K250 | 25 kg | 1 | 1000 MPa | 0,25 |

| K355 | 45 kg | 1 | 1000 MPa | 0,25 / 0,30 |

| P5 | 5 kg | 4 | 1000 MPa | 0,25 |

| P10 | 10 kg | 2 | 1000 MPa | 0,20 / 0,25 / 0,30 |

| P15 | 20 kg | 1 | 1000 MPa | 0,25 / 0,30 |

Coated erode wire

gapstar® ONE – Neue Generation der Hochleistungsdrähte mit patentierter bedra TRIMPAC Technologie

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| B8 | 8 kg | 2 | 400 / 500 / 1000 MPa | 0,20 (nur 1000) / 0,25 / 0,30 (nur 1000) |

| B16 | 16 kg | 1 | 400 / 500 / 1000 MPa | 0,20 (nur 1000) / 0,25 / 0,30 (nur 1000) |

| K250 | 25 kg | 1 | 400 / 500 / 1000 MPa | 0,25 / 0,30 (nur 1000) |

| K355 | 45 kg | 1 | 400 / 500 / 1000 MPa | 0,25 / 0,30 (nur 1000) |

| P5 | 5 kg | 4 | 400 / 500 / 1000 MPa | 0,20 (nur 1000) / 0,25 / 0,30 (nur 1000) |

| P10 | 10 kg | 2 | 400 / 500 / 1000 MPa | 0,20 (nur 1000) / 0,25 / 0,30 (nur 1000) |

| P15 | 20 kg | 1 | 400 / 500 / 1000 MPa | 0,20 (nur 1000) / 0,25 / 0,30 (nur 1000) |

boline H – Gamma-Phasen-Draht, made by bedra

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K160 | 8 kg | 2 | 900 MPa | 0,20 / 0,25 / 0,30 |

| K200 | 16 kg | 1 | 900 MPa | 0,20 ´/ 0,25 / 0,30 |

| K250 | 25 kg | 1 | 900 MPa | 0,25 / 0,30 |

| P10 | 10 kg | 2 | 900 MPa | 0,20 / 0,25 / 0,30 |

| P15 | 20 kg | 1 | 900 MPa | 0,25 / 0,30 |

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K160 | 8 kg | 2 | 500 MPa | 0,25 |

| K200 | 16 kg | 1 | 500 MPa | 0,25 |

topas® PLUS G – Special electrode for high cutting performance in combination with highest precision on AGIE-machines

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| B8 | 8 kg | 2 | 1000 MPa | 0,20 / 0,25 |

| B16 | 16 kg | 1 | 1000 MPa | 0,20 / 0,25 |

| K250 | 25 kg | 1 | 1000 MPa | 0,20 / 0,25 |

cobracut® – For conical cuts

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| B4 | 4 kg | 1 | 500 MPa | 0,20 / 0,25 |

| B8 | 8 kg | 2 | 500 MPa | 0,20 / 0,25 |

| B16 | 16 kg | 1 | 500 MPa | 0,20 / 0,25 |

| K250 | 25 kg | 1 | 500 MPa | 0,20 / 0,25 |

cobracut® Typ A – For highest precision

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| B4 | 4 kg | 1 | 900 MPa | 0,15 |

| B8 | 8 kg | 2 | 900 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| B16 | 16 kg | 1 | 900 MPa | 0,20 / 0,25 / 0,30 |

| K250 | 25 kg | 1 | 900 MPa | 0,25 / 0,30 |

| K355 | 45 kg | 1 | 900 MPa | 0,25 / 0,30 |

cobracut® Typ G – For highest precision, even with large conics on toroid-guided machines

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| B8 | 8 kg | 2 | 900 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| B16 | 16 kg | 1 | 900 MPa | 0,20 / 0,25 / 0,30 |

| K250 | 25 kg | 1 | 900 MPa | 0,20 / 0,25 / 0,30 |

| K355 | 45 kg | 1 | 900 MPa | 0,30 |

megacut® Typ A – For highest precision

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K160 | 8 kg | 2 | 900 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| K200 | 16 kg | 1 | 900 MPa | 0,20 / 0,25 / 0,30 |

| P5 | 5 kg | 2 | 900 MPa | 0,15 / 0,20 / 0,25 |

| P10 | 10 kg | 2 | 900 MPa | 0,20 / 0,25 / 0,30 |

| P15 | 20 kg | 1 | 900 MPa | 0,20 / 0,25 / 0,30 |

megacut® plus – For high cutting performance at an attractive price

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K160 | 8 kg | 2 | 900 MPa | 0,25 |

| P5 | 5 kg | 4 | 900 MPa | 0,25 |

| P10 | 10 kg | 2 | 900 MPa | 0,25 |

| P15 | 20 kg | 1 | 900 MPa | 0,25 |

topas® plus H – High-performance wire for Makino machines

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| B8 | 8 kg | 2 | 800 MPa | 0,20 / 0,25 / 0,30 |

| B16 | 16 kg | 1 | 800 MPa | 0,20 / 0,25 / 0,30 / 0,33 |

| K250 | 25 kg | 1 | 800 MPa | 0,20 / 0,25 / 0,30 / 0,33 |

| K355 | 45 kg | 1 | 800 MPa | 0,25 / 0,30 / 0,33 |

| P5 | 5 kg | 4 | 800 MPa | 0,20 / 0,25 / 0,30 |

| P10 | 10 kg | 2 | 800 MPa | 0,20 / 0,25 / 0,30 |

| P15 | 20 kg | 1 | 800 MPa | 0,20 / 0,25 / 0,30 |

topas® plus X – For Charmilles-machines with X-technology

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| B8 | 8 kg | 2 | 500 MPa | 0,25 / 0,30 / 0,33 |

| B16 | 16 kg | 1 | 500 MPa | 0,25 / 0,30 / 0,33 |

| K250 | 25 kg | 1 | 500 MPa | 0,25 / 0,30 / 0,33 |

| K355 | 45 kg | 1 | 500 MPa | 0,30 / 0,33 |

| P10 | 10 kg | 2 | 500 MPa | 0,25 / 0,30 |

| P15 | 20 kg | 1 | 500 MPa | 0,25 / 0,30 |

broncocut® Typ X – Fast and accurate

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| B4 | 4 kg | 1 | 520 MPa | 0,25 |

| B8 | 8 kg | 2 | 520 MPa | 0,25 / 0,30 |

| K125 | 3,5 kg | 4 | 520 MPa | 0,25 |

| K250 | 25 kg | 1 | 520 MPa | 0,25 / 0,30 |

| K355 | 45 kg | 1 | 520 MPa | 0,25 / 0,30 |

| P5 | 4 kg | 4 | 520 MPa | 0,25 / 0,30 |

| P10 | 10 kg | 2 | 520 MPa | 0,25 / 0,30 |

| P15 | 20 kg | 1 | 520 MPa | 0,25 / 0,30 |

Fine Wire

microcut® MF2A – Für anspruchsvollste Mikroerosionsanwendungen die eine noch höhere Available tensile strength erfordern

| Coil type | Länge | VPE coil | Available tensile strength | Dimensions |

| BK100 | 5000 m | 1 | 2400 MPa | 0,05 / 0,07 |

| BK100 | 10.000 m | 1 | 2400 MPa | 0,05 / 0,07 |

| B4 | 20.000 m | 1 | 2400 MPa | 0,07 / 0,10 |

| B4 | 30.000 m | 1 | 2400 MPa | 0,07 / 0,10 |

microcut® CCA – Für hohe Anforderungen bei der Mikroerosion

| Coil type | Länge | VPE coil | Available tensile strength | Dimensions |

| B4 | 10.000 m | 1 | 1000 MPa | – |

| B4 | 20.000 m | 1 | 1000 MPa | 0,07 / 0,10 |

| B4 | 30.000 m | 1 | 1000 MPa | 0,07 / 0,10 |

| B4 | 60.000 m | 1 | 1000 MPa | 0,10 |

microcut® SF – Gamma-Phasen-Feinstdraht für wirtschaftliche Bearbeitung in der Mikroerosion

| Coil type | Länge | VPE coil | Available tensile strength | Dimensions |

| B4 | 20.000 m | 1 | 1200 MPa | 0,07 / 0,10 |

| B4 | 30.000 m | 1 | 1200 MPa | 0,07 / 0,10 |

| B4 | 60.000 m | 1 | 1200 MPa | 0,10 |

Bare wire / Brass wire

dacoCut®

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K100 | 2 kg | 16 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| K125 | 3,5 kg | 4 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| K160 | 7 kg | 2 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| K200 | 16 kg | 1 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| K250 | 25 kg | 1 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| K355 | 45 kg | 1 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| P3 | 3 kg | 4 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| P5 | 5 kg | 2 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| P10 | 10 kg | 2 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

| P15 | 20 kg | 1 | 400 / 500 / 900 / 950 / 1000 MPa | 0,15 / 0,20 / 0,25 / 0,30 |

Galvanized erode wire

dacoCut®-A

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K100 | 2 kg | 16 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| K125 | 3,5 kg | 4 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| K160 | 7 kg | 2 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| K200 | 16 kg | 1 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| K250 | 25 kg | 1 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| K355 | 45 kg | 1 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| P3 | 3 kg | 4 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| P5 | 5 kg | 2 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| P10 | 10 kg | 2 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

| P15 | 20 kg | 1 | 500 / 900 / 950 / 1000 MPa | 0,10 (ab 900) / 0,15 / 0,20 / 0,25 / 0,30 |

Coated erode wire

dacoCut®-X

| Coil type | Fill weight | VPE coil | Available tensile strength | Dimensions |

| K125 | 3,5 kg | 2 | 500 MPa | 0,20 / 0,25 |

| K160 | 8 kg | 2 | 500 MPa | 0,20 / 0,25 |

| K200 | 16 kg | 1 | 500 MPa | 0,20 / 0,25 |

| K250 | 25 kg | 1 | 500 MPa | 0,20 / 0,25 |

| K355 | 45 kg | 1 | 500 MPa | 0,20 / 0,25 |

| P5 | 5 kg | 2 | 500 MPa | 0,20 / 0,25 |

| P10 | 10 kg | 2 | 500 MPa | 0,20 / 0,25 |

| P15 | 20 kg | 1 | 500 MPa | 0,20 / 0,25 |

AGIE BROTHERCHARMILLES CHMER FANUC HITACHIMAKINOMITSUBISHISEIBUSODICKSENKEROSION

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Filter cartridge White

|

– | 0320028 Filter cartridge for Agie, Charmilles, Makino Dimensions: 65 x 250 mm Filtration rating: 5 µm „without grooves“ Packaging unit 1 piece/s |

– | – |

| Filter cartridge White

|

– | 0320028.R Filter cartridge for Agie, Charmilles, Makino Dimensions: 65 x 250 mm Filtration rating: 5 µm „with groove“ Packaging unit 1 piece/s |

– | – |

| Plate filter Hansen / OPS Ingersoll

|

Agietron (50, 100, 200, 300) (1, 2, 3, 4, 5, 6) U Agieeloxmondo (20, 30) Agietoron Integral (2, 3) |

0311005 Dimensions: Ø150 x 31,5 x 365 mm Filtration rating: 5 µm Filter surface: 3,80 m² Flow direction: from outside to inside Differential pressure: max. 1,5 bar Connection: Center pipe Model: plate filter Weight: 2,3 kg VE: 6 piece/s |

EM 114/5 Original Chemo-Filter, Made in Germany Dimensions: Ø150 x Ø 31,5 x 365 mm Filtration rating: 5 µm Filter surface: 3,80 m² Flow direction: from outside to inside Differential pressure: max. 1,5 bar Model: Metal Weight: 2,4 kg VE: 6 piece/s |

– |

| Plate filter Agie / Charmilles / Japax

|

Agiecut (100D, 150, 200D, 250, 300D) Evolution (2, 3) DEM (215, 250, 315,7 00) AC Progress (VP2, VP3, VP4) |

0312208 Dimensions: Ø 150 x 31 x 375 mm Filtration rating: 3 – 5 µm Filter surface: 3,2 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper Star with handle Weight: 1 kg VE: 4 piece/s |

0312208C (EM 1204 K/5 schwarz) Made in Germany Dimensions: Ø 150 x 32 x 375 mm Filtration rating: 5 µm Filter surface: 3,03 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: metal free, Plastic version Field of application: Wire- and Sparkerosion Packaging unit: 4 piece/s |

H15190/16 Original Mann + Hummel Dimensions: Ø 150 x Ø 32 x 375 mm Filtration rating: 3-5 µm Filter surface: 3,1 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: metal free, Plastic version FilterWeight: 0,8 kg Packaging unit: 4 St. per carton |

| Plate filter Agie / Charmilles

|

Agiecut (100D, 150, 200D, 250, 300D) Evolution (2, 3) DEM (215, 250, 315, 700) AC Progress (VP2, VP3, VP4) |

0320003 Dimensions: Ø 150 x 31 x 364 mm Filtration rating: 3 – 5 µm Filter surface: 3,23 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Center pipe Model: Metal FilterWeight: 1,6 kg Packaging unit: 4 piece/s |

– | H15475 Original Mann + Hummel Dimensions: Ø 150 x Ø 32 x 364 mm Filtration rating: 3 – 5 µm Filter surface: 4,7 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal FilterWeight: 1,7 kg Packaging unit 4 St. per carton |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Plate filter Brother / Mitsubishi

|

HS-(300, 350, 3100, 3600,5100), HS-50A, 70A |

0312110P Dimensions: Ø 300 x 29 x 500 mm Filtration rating: 3 – 5 µm Filter surface: 9,5 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 5,1 kg VE: 2 piece/s |

EM 150/5 Original Chemo-Filter,Made in Germany Dimensions: Ø300 x Ø 29 x 504 mm Filtration rating: 5 µm Filter surface: 10,2 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Packaging unit 1 St. per carton |

H31967/20 Original Mann + Hummel Dimensions: Ø 302 x Ø 29 x 507 mm Filtration rating: 3 – 5 µm Filter surface: 9,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal FilterWeight: 7,0 kg Packaging unit 1 St. per carton |

„Cleanstar“ Filter Mitsubishi / Brother |

HS-(300, 350, 3100, 3600,5100), HS-50A, 70A | 0312110-UTK Dimensions: Ø 300 x 29 x 500 mm Filtration rating: 1-3 µm Filter surface: 17,11 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 7,5 kg Packaging unit: 2 piece/s |

150/3 Original Chemo-Filter,Made in Germany Dimensions: Ø300 x Ø 29 x 504 mm Filtration rating: 3 µm Filter surface: 11,16 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Packaging unit 1 St. per carton |

– |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Filter cartridge White

|

– | 0320028 Filter cartridge for Agie, Charmilles, Makino Dimensions: 65 x 250 mm Filtration rating: 5 µm „without grooves“ Packaging unit 1 piece/s |

– | – |

| Filter cartridge White

|

– | 0320028.R Filter cartridge for Agie, Charmilles, Makino Dimensions: 65 x 250 mm Filtration rating: 5 µm „with groove“ Packaging unit 1 piece/s |

– | – |

| Plate filter Hansen / OPS Ingersoll“

|

ROBOFORM (20, 30, 40, 41, 100 ,200, 400,810, 2000, 4000, 7010, 8010, 9010, 22, 35, 35P), ELERODA (110, 220, 430) |

0311005 Dimensions: Ø150 x 31,5 x 365 mm Filtration rating: 5 µm Filter surface: 3,80 m² Flow direction: from outside to inside Differential pressure: max. 1,5 bar Connection: Center pipe Model: plate filter Weight: 2,3 kg VE: 6 piece/s |

EM 114/5 Original Chemo-Filter, Made in Germany Dimensions: Ø150 x Ø 31,5 x 365 mm Filtration rating: 5 µm Filter surface: 3,80 m² Flow direction: from outside to inside Differential pressure: max. 1,5 bar Model: Metal Weight: 2,4 kg VE: 6 piece/s |

– |

| Plate filter Agie / Charmilles / Japax

|

AM370, Robofil (100, 200, 290, 310, 330, 400, 510, 600, 1020, 2020, 4020, 6020,1030, 2030, 4030, 6030) |

0312208 Dimensions: Ø 150 x 31 x 375 mm Filtration rating: 3 – 5 µm Filter surface: 3,2 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper Star with handle Weight: 1 kg VE: 4 piece/s |

0312208C (EM 1204 K/5 schwarz) Made in Germany Dimensions: Ø 150 x 32 x 375 mm Filtration rating: 5 µm Filter surface: 3,03 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: metal free, Plastic version Field of application: Wire- and Sparkerosion Packaging unit: 4 piece/s |

H15190/16 Original Mann + Hummel Dimensions: Ø 150 x Ø 32 x 375 mm Filtration rating: 3-5 µm Filter surface: 3,1 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: metal free, Plastic version FilterWeight: 0,8 kg Packaging unit: 4 St. per carton |

| Plate filter Agie / Charmilles

|

Roboform (20, 30, 40, 41, 100, 200, 400, 810, 2000, 4000, 7010 ,8010, 9010), Eleroda (110, 220, 430) |

0312201 Dimensions: Ø 150 x 31 x 355 mm Filtration rating: 15 µm Filter surface: 1,9 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper star with Handle Weight: 1 kg VE: 6 piece/s |

EM 204/15 Original CHEMO-Filter, Made in Germany Dimensions: Ø150 x Ø31,5 x 365 mm Filtration rating: 10-15 µm Filter surface: 2,20 m² Flow direction: from outside to inside Differential pressure: max. 4 bar Model: Paper starFilter Field of application: Wire- and Sparkerosion Packaging unit: 6 St. per carton |

– |

| Plate filter Seibu

|

AM370, Robofil (100, 200, 290, 310, 330, 400, 510, 600, 1020, 2020, 4020, 6020, 1030, 2030, 4030, 6030) |

0312209 Dimensions: Ø 150 x 31 x 375 mm Filtration rating: 10 µm Filter surface: 3,2 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper Star with handle Weight: 1 kg VE: 4 piece/s |

EM 1204K/10 Original CHEMO-Filter, Made in Germany Dimensions: Ø 150 x Ø 31,5 x 375 mm Filtration rating: 10 µ Filter surface: 2,97 m² Flow direction: from outside to inside Differential pressure: max. 4 bar Model: metal free, Plastic version Weight: 1 kg Packaging unit: 4 St. per carton |

H15190/10 Original Mann + Hummel Dimensions: Ø 150 x Ø 32 x 375 mm Filtration rating: 10 µm Filter surface: 2,8 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: metal free, Plastic version FilterWeight: 0,7 kg Packaging unit: 4 St. per carton |

| Plate filter Agie / Charmilles

|

AM370, Robofil (100, 200, 290, 310, 330, 400, 510, 600, 1020, 2020, 4020, 6020, 1030, 2030, 4030, 6030) |

0320003 Dimensions: Ø 150 x 31 x 364 mm Filtration rating: 3 – 5 µm Filter surface: 3,23 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Center pipe Model: Metal FilterWeight: 1,6 kg Packaging unit: 4 piece/s |

– | H15475 Original Mann + Hummel Dimensions: Ø 150 x Ø 32 x 364 mm Filtration rating: 3 – 5 µm Filter surface: 4,7 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal FilterWeight: 1,7 kg Packaging unit 4 piece/s per carton |

| Plate filter Charmilles

|

ROBOFIL (240CC, 440CC, 640CC, 240SL, 440SL, 2050TW, 6050TW), CUT (200, 300, 400) |

0312026A (0312029MEK/0312029FEK) Dimensions: Ø 340 x 450 mm Filtration rating: 3 – 5 µm Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Central nipple Model: Metal, powder coated Weight: 7,8 kg VE: 2 piece/s |

EM 691/5 P Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x GA x 440 mm Filtration rating: 5 µm Filter surface: 20,4 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Plug connection Model: Metal, powder coated |

H342240/40 H342090 KIT Plastic version Original Mann + Hummel Dimensions: Ø 340 x 450 mm Filtration rating: 3-5 µm Filter surface: 22,4 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: Metal mit Packaging unit FilterWeight: 11,8 kg Packaging unit 1 St. per carton |

| Plate filter Fanuc Alpha / Sodick/ Charmilles

|

A300W, A320D, A350, A350W, A350S, A350SS, A350SSW, A500, A530D, A600W, A750W, A1000W, BF250, BF275, BF280L, BF320L | 0311008 Dimensions: Ø 340 x 46 x 450 mm Filtration rating: 3 – 5 µm Filter surface: 12,8 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 6,2 kg VE: 2 piece/s |

171/5 P Original Chemo-Filter, Made in Germany Dimensions: Ø340 x 47 x 420 mm Filtration rating: 3-5 µm Filter surface: 17,35 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal, powder coated Weight: 10,7 kg |

H341158/40 H341790 Plastic version Original Mann + Hummel Dimensions: Ø 340 x 46 x 450 mm Filtration rating: 3-5 µm Filter surface: 14,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Weight: ca. 8,8 kg Packaging unit: 1 St. per carton |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Plate filter Agie / Charmilles

|

CM Series | 0312201 Dimensions: Ø 150 x 31 x 355 mm Filtration rating: 15 µm Filter surface: 1,9 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper star with Handle Weight: 1 kg VE: 6 piece/s |

0312201 Dimensions: Ø 150 x 31 x 355 mm Filtration rating: 15 µm Filter surface: 1,9 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper star with Handle Weight: 1 kg VE: 6 piece/s |

– |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Plate filter Fanuc/Sodick

|

Model: O, P, Q, R, S, T, V Mate: W0, W1, W2, W3 α-0B, α-1B, α-0C, α-1C |

0311007 Dimensions: Ø 340 x 46 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,02 m² Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: Center pipe Model: Metal, powder coated Weight: 5,95 kg Packaging unit: 2 piece/s |

EM 163/5 Original CHEMO-Filter, Made in Germany Dimensions: Ø 340 x 47 x 306 mm Filtration rating: 5 µm Filter surface: 14,58 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Weight: 9,5 kg |

H341070/40 H341290/3 Plastic version Original Mann + Hummel Dimensions: Ø 340 x Ø 45,5 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 10,7 m², single bellow technology Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Connection: Center pipe Weight: 6,4 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Fanuc/Sodick

|

Model: O, P, Q, R, S, T, V Mate: W0, W1, W2, W3 α-0B, α-1B, α-0C, α-1C |

0311001-UT Made by OSHITARI Dimensions: 340 x 46 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,5 m² Differential pressure: max. 2,5 bar Flow direction: from outside to inside Made in Japan powder coated, corrosion resistant Weight: 3,5 kg Packaging unit 2 piece/s |

EM 411/3 Original Chemo-Filter, Made in Germany Dimensions: Ø340 x 47 x 306 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Center pipe Filter fabric: synthetic fleece Model: Metal |

– |

| „Cleanstar“ Filter Fanuc/Sodick

|

Model: O, P, Q, R, S, T, V Mate: W0, W1, W2, W3 α-0B, α-1B, α-0C, α-1C |

0311001-UTK Dimensions: Ø 340 x 46 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 15 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 6,5 kg Packaging unit: 2 piece/s |

EM 411/3 Original Chemo-Filter, Made in Germany Dimensions: Ø340 x 47 x 306 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Center pipe Model: Metal Filter fabric: synthetic fleece |

– |

| Plate filter Fanuc / Hitachi / Makino / Mitsubishi / Seibu

|

α-0iB, 1iB, 0ice, 1ice, 0icp, 0icp5, 0ic5, 1ic5, 0ic, 1ic | 0312024-G34 (0312024A) Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,6 m² Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: central nipple Model: Metal, powder coated Weight: 6,3 kg Packaging unit 2 piece/s |

EM 670/5 P Original Chemo-Filter, Made in Germany Dimensions: Ø340 x Ø76 x 300 mm Filtration rating: 3-5 µm Filter surface: 12 m² Flow direction: from outside to inside, Differential pressure: max. 3 bar Connection: Plug connection Model: Metal, powder coatedEM 670/5 MV Mantel Vlies |

H341390 Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: metal free, Plastic with double bellows Weight: 6,4 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Fanuc Alpha

|

α-0iB, 1iB, 0ice, 1ice, 0icp, 0icp5, 0ic5, 1ic5, 0ic, 1ic | 0312024A-UTK Made by OSHITARI Dimensions: 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 17 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Made in Japan powder coated / corrosion resistant Weight: 4,4 kg Packaging unit 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 “ Model: long-life, W-Falte Metal, powder coated Weight: 8,5 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Fanuc Alpha

|

α-0iB, 1iB, 0ice, 1ice, 0icp, 0icp5, 0ic5, 1ic5, 0ic, 1ic | 0312024A-UT Made by OSHITARI Dimensions: 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 17 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Made in Japan powder coated / corrosion resistant Weight: 4,4 kg Packaging unit 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 “ Model: long-life, W-Falte Metal, powder coated Weight: 8,5 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Fanuc Alpha

|

α-0iB, 1iB, 0ice, 1ice, 0icp, 0icp5, 0ic5, 1ic5, 0ic, 1ic | 0312024A-UTK Dimensions: Ø 340 x 340 mm Filtration rating: 1 – 2 µm Filter surface: 17 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Central nipple Model: Metal, powder coated Weight: 7 kg Packaging unit: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated Weight: 8,5 kg Packaging unit: 1 St. per carton |

| Plate filter Fanuc Alpha / Sodick/ Charmilles

|

MODEL (O,P,Q,R,S,T,V). TAPECUT(W0, W1) TAPECUT (W2,W3,W4). CUTMATE, CUT-αOA |

0311008 Dimensions: Ø 340 x 46 x 450 mm Filtration rating: 3 – 5 µm Filter surface: 12,8 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 6,2 kg Packaging unit: 2 piece/s |

EM 171/5 P Original Chemo-Filter, Made in Germany Dimensions: Ø340 x 47 x 420 mm Filtration rating: 3-5 µm Filter surface: 17,35 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal, powder coated |

H341158/40 H341790 Plastic version Original Mann + Hummel Dimensions: Ø 340 x 46 x 450 mm Filtration rating: 3-5 µm Filter surface: 14,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Weight: ca. 8,8 kg Packaging unit: 1 St. per carton |

| Plate filter Fanuc

|

Alpha 600 | 0312026A Dimensions: Ø 340 x 450 mm Filtration rating: 3 – 5 µm Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Central nipple Model: Metal, powder coated Weight: 7,8 kg Packaging unit: 2 piece/s |

EM 700/3 EM 700/3 P powder coated Original Chemo-Filter, Made in Germany Dimensions: Ø340 x 400 mm Filtration rating: 1-2 µm Flow direction: from outside to inside Differential pressure: max. 3 bar |

– |

| „Cleanstar“ Filter Fanuc Alpha

|

Alpha 600 | 0312026A-UT Made by OSHITARI Dimensions: 340 x 450 mm Filtration rating: 1 – 2 µm Filter surface: 26 m² Differential pressure: max. 3 bar Flow direction: from outside to inside powder coated / corrosion resistant Gesicht: 7,3 kg / piece/s Packaging unit 2 piece/s |

EM 700 EM 700 P powder coated Original Chemo-Filter, Made in Germany Dimensions: Ø340 x 400 mm Filtration rating: 1-2 µm Flow direction: from outside to inside Differential pressure: max. 3 bar |

– |

| „Cleanstar“ Filter Fanuc Alpha

|

Alpha 600 | 0312026A-UTK Dimensions: Ø 340 x 450 mm Filtration rating: 1-2 µm Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Central nipple Model: Metal, powder coated Weight: 8,2 kg Packaging unit: 2 piece/s |

EM 700 EM 700 P powder coated Original Chemo-Filter, Made in Germany Dimensions: Ø340 x 400 mm Filtration rating: 1-2 µm Flow direction: from outside to inside Differential pressure: max. 3 bar |

– |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Plate filter Makino / Mitsubishi / Hitachi

|

Q Series H-CUT (3,4,5,6,8,3HP,203) Q | 0312022 Dimensions: Ø 300 x 29 x 250 mm Filtration rating: 3 – 5 µm Filter surface: 8,1 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Center pipe, Side nipple Model: Metal, powder coated Weight: 4 kg Packaging unit: 2 piece/s |

– | – |

| Plate filter Fanuc / Hitachi / Makino / Mitsubishi / Seibu

|

CUT203F2, 203R ,203Y, 254, 254RS, 254RH, 254Y, 355, 355R, 355RS 355RH, 355Y | 0312024-G34 (0312024-KC/-KS) Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,6 m² Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: central nipple Model: Metal, powder coated Weight: 6,3 kg Packaging unit: 2 piece/s |

EM 670/5 P Original Chemo-Filter, Made in Germany Dimensions: Ø340 x Ø76 x 300 mm Filtration rating: 3-5 µm Filter surface: 12 m² Flow direction: from outside to inside, Differential pressure: max. 3 bar Connection: Plug connection Model: Metal, powder coated EM 670/5 MV Mantel Vlies |

H341390 Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: metal free, Plastic with double bellows FilterWeight: 6,4 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

CUT203F2, 203R ,203Y, 254, 254RS, 254RH, 254Y, 355, 355R, 355RS, 355RH, 355Y | 0312024-UT Dimensions: 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,5 m² Flow direction: from outside to inside Differential pressure: max. 2,5 bar Model: Metal – plastic lid and base powder coated / corrosion resistant Made in Japan Weight: 3,2 kg Packaging unit: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT H341490/14 KIT Plastic version Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

CUT203F2, 203R ,203Y, 254, 254RS, 254RH, 254Y, 355, 355R, 355RS, 355RH, 355Y | 0312024-UTK Dimensions: Ø 340 x 340 mm Filtration rating: 1 – 2 µm Filter surface: 17 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Central nipple Model: Metal, powder coated Weight: 7 kg VE: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT H341490/14 KIT Plastic version Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

CUT203F2, 203R ,203Y, 254, 254RS, 254RH, 254Y, 355, 355R, 355RS, 355RH, 355Y | 0312024-UTK300 Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 15 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Central nipple Model: Metal, powder coated Weight: 6,5 kg VE: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT H341490/14 KIT Plastic versionOriginal Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Filter cartridge White

|

– | 0320028 Dimensions: 65 x 250 mm Filtration rating: 5 µm „without grooves“ Packaging unit: 1 piece/s |

– | – |

| Filter cartridge White

|

CUT203F2, 203R ,203Y, 254, 254RS, 254RH, 254Y, 355, 355R, 355RS, 355RH, 355Y | 0320028.R Dimensions: 65 x 250 mm Filtration rating: 5 µm „with groove“ Packaging unit: 1 piece/s |

– | – |

| Plate filter Sodick / Seibu / Makino SEM  |

ED22 | 0312116 Dimensions: Ø150 x Ø 73 x 455 mm Filtration rating: 15 µm Filter surface: 2,45 m² Flow direction: from outside to inside Differential pressure: max. 2 bar Connection: Center pipe Model: Paper star Weight: 1,3 kg Packaging unit: 6 piece/s |

EM 130/15 Original Chemo-Filter, Made in Germany Dimensions: Ø150 x Ø 37 x 455 mm Filtration rating: 15 µm Filter surface: 2,73 m² Flow direction: from outside to inside Differential pressure: max. 2 bar Model: Metal Packaging unit: 2 St. per carton |

– |

| Plate filter Makino / Sodick

|

EC(3025, 3040, 3141, 7050, 3141S, 108), EA3040 | 0311003 Dimensions: Ø 260 x 46 x 280 mm Filtration rating: 3 – 5 µm Filter surface: 5,1 qm Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Center pipe Model: Paper star Weight: 2,9 kg Packaging unit: 2 piece/s |

– | H26644/20 Original Mann + Hummel Dimensions: Ø 261 x Ø 46 x 280 mm Filtration rating: 3 – 5 µm Filter surface: 5,4 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal FilterWeight: 3,7 kg Packaging unit: 1 St. per carton |

| Plate filter Makino / Yougar

|

EE-3, 6, 6L, EQ-5, EH-3, 6, EQH-5, EQF-5, MUQ-32, MU-43 | 0312022 Dimensions: Ø 300 x 29 x 250 mm Filtration rating: 3 – 5 µm Filter surface: 8,1 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Center pipe, Side nipple Model: Metal, powder coated Weight: 4 kg Packaging unit: 2 piece/s |

– | – |

| Plate filter Makino / Mitsubishi

|

EE-3, 6, 6L, EQ-5, EH-3, 6, EQH-5, EQF-5, MUQ-32, MU-43 | 0312020 Dimensions: Ø 300 x 500 mm Filtration rating: 3 – 5 µm Filter surface: 16,36 qm Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: central nipple Model: Metal, powder coated Weight: 6,2 kg Packaging unit: 2 piece/s |

EM 550/5 Original Chemo-Filter, Made in Germany Dimensions: Ø300 x 47/NA x 500 mm Filtration rating: 3-5 µm Filter surface: 15,17 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Plug connection Model: Metal |

H311680-14 KIT Original Mann + Hummel Dimensions: Ø 302 x 501 mm Connection: G 3/4 “ Filtration rating: 3 – 5 µm Filter surface: 17,4 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal, corrosion resistant FilterWeight: 7,6 kg Packaging unit: 1 St. per carton |

| Plate filter Makino / Mitsubishi

|

EE-3, 6, 6L, EQ-5, EH-3, 6, EQH-5, EQF-5, MUQ-32, MU-43 | 0312020-KS Dimensions: Ø 300 x 29 x 500 mm Filtration rating: 3 – 5 µm Filter surface: 16,2 qm Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: Center pipe, Side nipple G3/4″ Model: Metal, powder coated Weight: 6,2 kg Packaging unit: 2 piece/s |

EM 550/5 Original Chemo-Filter, Made in Germany Dimensions: Ø300 x 47/NA x 500 mm Filtration rating: 3-5 µm Filter surface: 15,17 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Plug connection Model: Metal |

H311033/20 Original Mann + Hummel Dimensions: Ø 302 x 503 mm Filtration rating: 3 – 5 µm Filter surface: 9,9 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal FilterWeight: 6,6 kg Packaging unit: 1 St. per carton |

| Plate filter Fanuc / Hitachi / Makino / Mitsubishi / Seibu

|

EC-32, EC-64, ECQ-53, U-53, U-32, U-53K, U-32K, SP43, SP-64, EU64 | 0312024-G34 (0312024-KC/-KS) Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,6 m² Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: central nipple Model: Metal, powder coated Weight: 6,3 kg Packaging unit: 2 piece/s |

EM 670/5 P Original Chemo-Filter, Made in Germany Dimensions: Ø340 x Ø76 x 300 mm Filtration rating: 3-5 µm Filter surface: 12 m² Differential pressure: max. 3 bar Flow direction: from outside to inside, Connection: Plug connection Model: Metal, powder coatedEM 670/5 MV Mantel Vlies |

H341390 Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: metal free, Plastic with double bellows FilterWeight: 6,4 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

EC-32, EC-64, ECQ-53, U-53, U-32, SP43, SP-64, EU64 | 0312024-UT Made by OSHITARI Dimensions: 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,5 m² Differential pressure: max. 2,5 bar Flow direction: from outside to inside Model: Metal – plastic lid and base powder coated / corrosion resistant Made in Japan Weight: 3,2 kg Packaging unit: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT H341490/14 KIT Plastic version Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton |

| „„Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

EC-32, EC-64, ECQ-53, U-53, U-32, SP43, SP-64, EU64 | 0312024-UTK300 Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 15 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Central nipple Model: Metal, powder coated Weight: 6,5 kg Packaging unit: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT H341490/14 KIT Plastic version Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Plate filter Makino / Mitsubishi / Hitachi

|

DWC-90B, 90SB, 110A, 110SA, DWC-90Z, 90SZ, 90SZP, 110Z, 110SZ, 110SZP, 110PA | 0312022 Dimensions: Ø 300 x 29 x 250 mm Filtration rating: 3 – 5 µm Filter surface: 8,1 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Center pipe, Side nipple Model: Metal, powder coated Weight: 4 kg Packaging unit: 2 piece/s |

– | – |

| Plate filter Makino / Mitsubishi

|

DWC-90B, 90SB, 110A, 110SA, DWC-90Z, 90SZ, 90SZP, 110Z, 110SZ, 110SZP, 110PA | 0312020 Dimensions: Ø 300 x 500 mm Filtration rating: 3 – 5 µm Filter surface: 16,36 qm Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: central nipple Model: Metal, powder coated Weight: 6,2 kg Packaging unit: 2 piece/s |

EM 550/5 | H311680-14 KIT Original Mann + Hummel Dimensions: Ø 302 x 501 mm Filtration rating: 3 – 5 µm Filter surface: 17,4 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: Metal, corrosion resistant FilterWeight: 7,6 kg Packaging unit: 1 St. per carton |

| Plate filter Makino / Mitsubishi

|

DWC-90B, 90SB, 110A, 110SA, DWC-90Z, 90SZ, 90SZP, 110Z, 110SZ, 110SZP, 110PA | 0312020-KS Dimensions: Ø 300 x 29 x 500 mm Filtration rating: 3 – 5 µm Filter surface: 16,2 qm Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: Center pipe, Side nipple G3/4″ Model: Metal, powder coated Weight: 6,2 kg Packaging unit: 2 piece/s |

EM 550/5 | H311033/20 Original Mann + Hummel Dimensions: Ø 302 x 503 mm Filtration rating: 3 – 5 µm Filter surface: 9,9 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal FilterWeight: 6,6 kg Packaging unit: 1 St. per carton |

| Plate filter Brother / Mitsubishi

|

DWC (70, 90, 90P, 110, 200, 400) F, G, H, DWC (90, 110, 200) U, DWC (90, 110, 200, 300, 400, 500) HA, DWC (90C1, 90C2) DWC (110C1, 110C2) | 0312110P Dimensions: Ø 300 x 29 x 500 mm Filtration rating: 3 – 5 µm Filter surface: 9,5 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 5,1 kg Packaging unit: 2 piece/s |

EM 150/5 | H31967/20 Original Mann + Hummel Dimensions: Ø 302 x Ø 29 x 507 mm Filtration rating: 3 – 5 µm Filter surface: 9,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal FilterWeight: 7,0 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Mitsubishi / Brother

|

DWC (70, 90, 90P, 110, 200, 400) F, G, H, DWC (90, 110, 200) U, DWC (90, 110, 200, 300, 400, 500) HA, DWC (90C1, 90C2) DWC (110C1, 110C2) | 0312110-UTK Dimensions: Ø 300 x 29 x 500 mm Filtration rating: 1-3 µm Filter surface: 17,11 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 7,5 kg Packaging unit: 2 piece/s |

150/3 | – |

| Plate filter Fanuc / Hitachi / Makino / Mitsubishi / Seibu

|

CX Series CX10,CX20,CX2. FX Series FX10,FX20,FX30. FX-K Series, QA, RA, FA, MV, NA | 0312024-G34 (0312024-KC/-KS) Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,6 m² Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: central nipple Model: Metal, powder coated Weight: 6,3 kg Packaging unit: 2 piece/s |

EM 670/5 P | H341390 Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: metal free, Plastic with double bellows FilterWeight: 6,4 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

CX Series CX10, CX20, CX2. FX Series FX10, FX20, FX30, FX-K, QA, RA, FA, PA, MV, NA | 0312024-UT Made by OSHITARI Dimensions: 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,5 m² Differential pressure: max. 2,5 bar Flow direction: from outside to inside Model: Metal – plastic lid and base powder coated / corrosion resistant Made in Japan Weight: 3,2 kg Packaging unit: 2 piece/s |

EM 401/3 | H341480/14 KIT H341490/14 KIT Plastic version Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

CX Series CX10, CX20, CX2, FX Series FX10, FX20, FX30, FX-K, QA, RA, PA, NA | 0312024-UTK Dimensions: Ø 340 x 340 mm Filtration rating: 1 – 2 µm Filter surface: 17 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Central nipple Model: Metal, powder coated Weight: 7 kg Packaging unit: 2 piece/s |

EM 401/3 | H341480/14 KIT H341490/14 KIT Plastic version Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

CX Series CX10, CX20, CX2, FX Series FX10, FX20, FX30, FX-K, QA, RA, PA, NA und FA, BA, MV | 0312024-UTK300 Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 15 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Central nipple Model: Metal, powder coated Weight: 6,5 kg Packaging unit: 2 piece/s |

EM 401/3 | H341480/14 KIT H341490/14 KIT Plastic version Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton |

| Plate filter Charmilles / Mitsubishi FX

|

CX Series CX10, CX20, CX2, FX Series FX10, FX20, FX30, FX-K Series, QA, RA, FA, PA | 0312025 Dimensions: Ø 340 x 46 x 450 mm Filtration rating: 3 – 5 µm Filter surface: 19,3 m² Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Center pipe, Side nipple Model: Metal, powder coated Weight: 7,9 kg Packaging unit: 2 piece/s |

690/5 690/5 p powder coated |

H342280/14 KIT Original Mann + Hummel Filter Dimensions: Ø 340 x 450 mm Filtration rating: 3 – 5 µm Filter surface: 22,6 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: W-Pleat Technology / Long Life Filter FilterWeight: 11,9 kg Packaging unit: 1 St. per carton |

| Filter Senkerosion Mitsubishi

|

Mitsubishi Senkerosion | 0311004 Dimensions: Ø300 x 300 mm, Connection G3/4″ N3-AL inklusive Filtration rating: 10 µm Filter surface: 7,54 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal |

EM 174/5 690/5 p powder coated |

– |

| Plate filter Charmilles

|

ROBOFIL (240CC, 440CC, 640CC, 240SL, 440SL, 2050TW, 6050TW),CUT (200, 300, 400) | 0312026A Dimensions: Ø 340 x 450 mm Filtration rating: 3 – 5 µm Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Central nipple Model: Metal, powder coated Weight: 7,8 kg Packaging unit: 2 piece/s |

EM 700/3 EM 700/3 p powder coated |

H342240/40 KIT Original Mann + Hummel Dimensions: Ø 340 x 450 mm Filtration rating: 3-5 µm Filter surface: 22,4 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: Metal with double bellows FilterWeight: 11,8 kg Packaging unit: 1 St. per carton |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Plate filter Seibu

|

EW- (25, 30N, 35, 250, 400,600). EW-(300, 400 ,600, 1000)F EW-(300, 450, 600, 700, 1000)K1. EW-(450600, 1000)K1FA EWP-(300A, 300B) |

0312210 Dimensions: 150 x 31,5 x 350 mm Filtration rating: 15 µm Filter surface: 1,90 m² Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Center pipe Model: Paper star Weight: 1 kg Packaging unit: 6 piece/s |

EM 304/15 Original Chemo-Filter, Made in Germany Dimensions: Ø150 x Ø 31,5 x 350 mm Filtration rating: 15 µm Filter surface: 1,7 m² Flow direction: from outside to inside Differential pressure: max. 2,5 bar Model: Paper star Packaging unit: 6 St. per carton |

– |

| Plate filter Sodick / Seibu / Makino SEM

|

E(150P,202H,300H,350M, 350N). EN(250,300,350)M |

0312116 Dimensions: Ø150 x Ø 73 x 455 mm Filtration rating: 15 µm Filter surface: 2,45 m² Flow direction: from outside to inside Differential pressure: max. 2 bar Connection: Center pipe Model: Paper star Weight: 1,3 kg Packaging unit: 6 piece/s |

EM 130/15 Original Chemo-Filter, Made in Germany Dimensions: Ø150 x Ø 37 x 455 mm Filtration rating: 15 µm Filter surface: 2,73 m² Flow direction: from outside to inside Differential pressure: max. 2 bar Model: Metal Packaging unit: 2 St. per carton |

– |

| Plate filter Makino / Mitsubishi

|

EWC-B3S, B3SL, B3SS EW-300K2, 450K2, 600K2, 700K2, 1000K2 |

0312020 Dimensions: Ø 300 x 500 mm Filtration rating: 3 – 5 µm Filter surface: 16,36 qm Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: central nipple Model: Metal, powder coated Weight: 6,2 kg Packaging unit: 2 piece/s |

EM 550/5 Original Chemo-Filter, Made in Germany Dimensions: Ø300 x 47/NA x 500 mm Filtration rating: 3-5 µm Filter surface: 15,17 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Plug connection Model: Metal |

H311680-14 KIT Original Mann + Hummel Dimensions: Ø 302 x 501 mm Filtration rating: 3 – 5 µm Filter surface: 17,4 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: Metal, corrosion resistant FilterWeight: 7,6 kg Packaging unit: 1 St. per carton |

| Plate filter Makino / Mitsubishi

|

EWC-B3S, B3SL, B3SS EW-300K2, 450K2, 600K2, 700K2, 1000K2 |

0312020-KS Dimensions: Ø 300 x 29 x 500 mm Filtration rating: 3 – 5 µm Filter surface: 16,2 qm Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: Center pipe, Side nipple G3/4″ Model: Metal, powder coated Weight: 6,2 kg Packaging unit: 2 piece/s |

EM 550/5 Original Chemo-Filter, Made in Germany Dimensions: Ø300 x 47/NA x 500 mm Filtration rating: 3-5 µm Filter surface: 15,17 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: Plug connection Model: Metal |

H311033/20 Original Mann + Hummel Dimensions: Ø 302 x 503 mm Filtration rating: 3 – 5 µm Filter surface: 9,9 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal FilterWeight: 6,6 kg Packaging unit: 1 St. per carton |

| Plate filter Fanuc / Hitachi / Makino / Mitsubishi / Seibu

|

EW-A5, A5S, C3, C3S, C5S, M350S, M500S, M750S, EWP-B3S3 | 0312024-G34 Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,6 m² Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: central nipple Model: Metal, powder coated Weight: 6,3 kg Packaging unit: 2 piece/s |

EM 670/5 P Original Chemo-Filter, Made in Germany Dimensions: Ø340 x Ø76 x 300 mm Filtration rating: 3-5 µm Filter surface: 12 m² Flow direction: from outside to inside, Differential pressure: max. 3 bar Connection: Plug connection Model: Metal, powder coated EM 670/5 MV Mantel Vlies |

H341390 Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Connection: G 3/4 “ Model: metal free, Plastic with double bellows FilterWeight: 6,4 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

EW-A5, A5S, C3, C3S, C5S, M350S, M500S, M750S, EWP-B3S3 | 0312024-UT Made by OSHITARI Dimensions: 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,5 m² Differential pressure: max. 2,5 bar Flow direction: from outside to inside Model: Metal – plastic lid and base powder coated / corrosion resistant Made in Japan Weight: 3,2 kg Packaging unit: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per cartonH341490/14 KIT Plastic version |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

EW-A5, A5S, C3, C3S, C5S, M350S, M500S, M750S, EWP-B3S3 | 0312024-UTK Dimensions: Ø 340 x 340 mm Filtration rating: 1 – 2 µm Filter surface: 17 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Central nipple Model: Metal, powder coated Weight: 7 kg Packaging unit: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton H341490/14 KIT Plastic version |

| „Cleanstar“ Filter Hitachi / Makino / Mitsubishi

|

EW-A5, A5S, C3, C3S, C5S, M350S, M500S, M750S, EWP-B3S3 | 0312024-UTK300 Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 15 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Central nipple Model: Metal, powder coated Weight: 6,5 kg VE: 2 piece/s |

EM 401/3 Original Chemo-Filter, Made in Germany Dimensions: Ø 340 x NA x 300 mm Filtration rating: 1-2 µm Filter surface: 16,10 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: Plug connection Filter fabric: synthetic fleece Model: Metal |

H341480/14 KIT Original Mann + Hummel Dimensions: Ø 340 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,9 m² Differential pressure: max. 3 bar Flow direction: from outside to inside Connection: G 3/4 „, Model: long-life, W-Falte Metal, powder coated FilterWeight: 8,5 kg Packaging unit: 1 St. per carton H341490/14 KIT Plastic version |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Plate filter Seibu

|

(330, 453, 654) W. AW(330, 453). EPOC(300, 500, 600, 800), AP (150, 300) G3A, GOW(3,5). EPOC (3WW, 3WS, 5W40W) |

0312210 Dimensions: 150 x 31,5 x 350 mm Filtration rating: 15 µm Filter surface: 1,90 m² Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Center pipe Model: Paper star Weight: 1 kg Packaging unit: 6 piece/s |

EM 304/15 Original Chemo-Filter, Made in Germany Dimensions: Ø150 x Ø 31,5 x 350 mm Filtration rating: 15 µm Filter surface: 1,7 m² Flow direction: from outside to inside Differential pressure: max. 2,5 bar Model: Paper star Packaging unit: 6 St. per carton |

– |

| Plate filter Sodick / Seibu / Makino SEM

|

2NC, 30NC, 35NC, A2C, A3C, A4C, AP1, AP3, AP3R, A3R, EPOC2, 3, 4, FP2, K2CN, K3CN, EXC100, EXC100S, AP(150, 200, 300). AW330, AW453 | 0312116 Dimensions: Ø150 x Ø 73 x 455 mm Filtration rating: 15 µm Filter surface: 2,45 m² Flow direction: from outside to inside Differential pressure: max. 2 bar Connection: Center pipe Model: Paper star Weight: 1,3 kg Packaging unit: 6 piece/s |

EM 130/15 Original Chemo-Filter, Made in Germany Dimensions: Ø150 x Ø 37 x 455 mm Filtration rating: 15 µm Filter surface: 2,73 m² Flow direction: from outside to inside Differential pressure: max. 2 bar Model: Metal Packaging unit: 2 St. per carton |

– |

| Plate filter Makino / Sodick

|

A350, A350S, A350W, A350SSW, A500, A500W. AW (330, 453) AP(200, 300, 330, 450, 550) EPOC(300, 500, 600, 800, 1100) | 0311003 Dimensions: Ø 260 x 46 x 280 mm Filtration rating: 3 – 5 µm Filter surface: 5,1 qm Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Center pipe Model: Paper star Weight: 2,9 kg Packaging unit: 2 piece/s |

– | – |

| Plate filter Fanuc/Sodick

|

A300, A350, A350W, A500, A500W, A600, A600W, A750, A750W, A1000W, A500P, A500WP, A600P, A600WP. AP200L, 250L, 450L, 500L, AQ Series, AG Series, SL Series | 0311007 Dimensions: Ø 340 x 46 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 13,02 m² Flow direction: from outside to inside Differential pressure: max. 2,2 bar Connection: Center pipe Model: Metal, powder coated Weight: 5,95 kg Packaging unit: 2 piece/s |

EM 163/5 | H341070/40 Original Mann + Hummel Dimensions: Ø 340 x Ø 45,5 x 300 mm Filtration rating: 3 – 5 µm Filter surface: 10,7 m², single bellow technology Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Connection: Center pipe FilterWeight: 6,4 kg Packaging unit: 1 St. per carton |

| „Cleanstar“ Filter Fanuc/Sodick

|

A300, A350, A350W, A500, A500W, A600, A600W, A750, A750W, A1000W, A500P, A500WP, A600P, A600WP. AP200L, 250L, 450L, 500L, AQ Series, AG Series, SL Series | 0311001-UT Made by OSHITARI Dimensions: 340 x 46 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 14,5 m² Differential pressure: max. 2,5 bar Flow direction: from outside to inside Made in Japan powder coated, corrosion resistant Weight: 3,5 kg Packaging unit: 2 piece/s |

EM 411/3 | – |

| „Cleanstar“ Filter Fanuc/Sodick

|

A300, A350, A350W, A500, A500W, A600, A600W, A750, A750W, A1000W, A500P, A500WP, A600P, A600WP. AP200L, 250L, 450L, 500L, AQ Series, AG Series, SL Series A300, A350, A350W, A500, A500W, A600, A600W, A750, A750W, A1000W, A500P, A500WP, A600P, A600WP. AP200L, 250L, 450L, 500L, AQ Series, AG Series, SL Series |

0311001-UTK Dimensions: Ø 340 x 46 x 300 mm Filtration rating: 1 – 2 µm Filter surface: 15 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 6,5 kg VE: 2 piece/s |

EM 411/3 | – |

| Plate filter Fanuc Alpha / Sodick/ Charmilles

|

A300W, A320D, A350, A350W, A350S, A350SS, A350SSW, A500, A530D, A600W, A750W, A1000W, BF250, BF275, BF280L, BF320L | 0311008 Dimensions: Ø 340 x 46 x 450 mm Filtration rating: 3 – 5 µm Filter surface: 12,8 m² Flow direction: from outside to inside Differential pressure: max. 3,0 bar Connection: Center pipe Model: Metal, powder coated Weight: 6,2 kg VE: 2 piece/s |

EM 171/5 P | H341158/40 H341790 Plastic version Original Mann + Hummel Dimensions: Ø 340 x 46 x 450 mm Filtration rating: 3-5 µm Filter surface: 14,5 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Weight: ca. 8,8 kg Packaging unit: 1 St. per carton |

| Designation | Machine type | bunol | Chemo | Mann + Hummel |

| Filter Paper star

|

Makino Sodick |

0311003 Dimensions:: Ø 260 x 46 x 280 mm Filtration rating: 3 – 5 µm Filter surface: 5,1 qm Flow direction: from outside to inside Differential pressure: max. 2,5 bar Connection: Center pipe Model: Paper star Weight: 2,9 kg Packaging unit: 2 piece/s |

– | – |

| plate filter

|

Charmilles Agie Hansen OPS Ingersoll |

0311005 Dimensions: Ø150 x 31,5 x 365 mm Filtration rating: 5 µm Filter surface: 3,80 m² Flow direction: from outside to inside Differential pressure: max. 1,5 bar Connection: Center pipe Model: plate filter Weight: 2,3 kg Packaging unit: 6 piece/s |

EM 114/5 Original Chemo-Filter, Made in Germany Dimensions: Ø150 x Ø 31,5 x 365 mm Filtration rating: 5 µm Filter surface: 3,80 m² Flow direction: from outside to inside Differential pressure: max. 1,5 bar Model: Metal Weight: 2,4 kg Packaging unit: 6 piece/s |

– |

| Filter Paper star

|

Charmilles Agie Chmer |

0312201 Dimensions: Ø 150 x 31 x 355 mm Filtration rating: 15 µm Filter surface: 1,9 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper star with Handle Weight: 1 kg Packaging unit: 6 piece/s |

EM 204/15 Original CHEMO-Filter, Made in Germany Dimensions: Ø150 x Ø31,5 x 365 mm Filtration rating: 10-15 µm Filter surface: 2,20 m² Flow direction: from outside to inside Differential pressure: max. 4 bar Model: Paper Star Filter Field of application: Wire- and Sparkerosion Packaging unit: 6 St. per carton |

– |

| Filter Paper star

|

Charmilles Agie Japax |

0312208 Dimensions: Ø 150 x 31 x 375 mm Filtration rating: 3 – 5 µm Filter surface: 3,2 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper Star with handle Weight: 1 kg Packaging unit: 4 piece/s |

0312208C (EM 1204 K/5) Made in Germany Dimensions: Ø 150 x 32 x 375 mm Filtration rating: 5 µm Filter surface: 3,03 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: metal free, Plastic version Field of application: Wire- and Sparkerosion Packaging unit: 4 piece/s |

H15190/16 Original Mann + Hummel Dimensions: Ø 150 x Ø 32 x 375 mm Filtration rating: 3-5 µm Filter surface: 3,1 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: metal free, Plastic version FilterWeight: 0,8 kg Packaging unit: 4 St. per carton |

| Filter Paper star

|

Charmilles Agie Seibu |

0312209 Dimensions: Ø 150 x 31 x 375 mm Filtration rating: 10 µm Filter surface: 3,2 m² Flow direction: from outside to inside Differential pressure: max. 4,0 bar Connection: Center pipe Model: Paper Star with handle Weight: 1 kg Packaging unit: 4 piece/s |

EM 1204 K/10 Original CHEMO-Filter, Made in Germany Dimensions: Ø 150 x Ø 31,5 x 375 mm Filtration rating: 10 µ Filter surface: 2,97 m² Flow direction: from outside to inside Differential pressure: max. 4 bar Model: metal free, Plastic version Weight: 1 kg Packaging unit: 4 St. per carton |

H15190/10 Original Mann + Hummel Dimensions: Ø 150 x Ø 32 x 375 mm Filtration rating: 10 µm Filter surface: 2,8 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: metal free, Plastic version FilterWeight: 0,7 kg Packaging unit: 4 St. per carton |

| Filter Senkerosion Mitsubishi

|

Mitsubishi Senkerosion | 0311004 Dimensions: Ø300 x 300 mm, Connection G3/4″ N3-AL inklusive Filtration rating: 10 µm Filter surface: 7,54 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Packaging unit: 2 piece/s |

EM 174/5 Original Chemo-Filter Made in Germany Dimensions: Ø300 x 300 mm, Connection G3/4″ F61 Filtration rating: 5 µm Filter surface: 6,62 m² Flow direction: from outside to inside Differential pressure: max. 3 bar Model: Metal Packaging unit: 1 St |

The conductivity of water takes on a crucial key role in the erosion of wire. This is because if the conductivity is not constant due to lower quality, the characteristics change with regard to spark discharge between the electrode and the workpiece. These altered characteristics can lead to the part being produced is no longer alongside of outside of the tolerance margin to be created. In order to ensure the greatest possible safety for you, we solely deliver new resins.

Together with our long-term supplier Purolite Deutschalnd GmbH, we have succeeded in developing a premium resin exclusively for HGH, which will provide the user with a substantial extension of service life.

For 95 % of the application cases our premium Harz MB58 is used. If however highly precise cuts are necessary in the area of hard metal processing, we recommend that you use our special resin MB400. This one-way combination resin distributes the percentage parts of anions and cations differently, which has a positive effect on the conductivity of water in hard metal processing.

The delivery is made in 25l containers

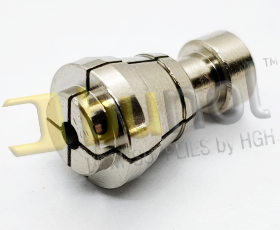

FANUC MAKINOMITSUBISHI SODICK

| OEM-No. Fanuc | Description | HGH Item No. |

| A290-8004-X410 | Felt insert Fanuc | 2456204 |

| A290-8004-X713 | Wire sub Pulley ceramic lower Ø 49 x 6,5 x 6 Fanuc | 2456303 |

| A290-8005-X722 | Isolation plate lower Fanuc | 2456003 |

| A290-8006-X707 | Wire sub Pulley ceramic lower Ø 64 x 6,5 x 6 Fanuc | 2456228 |

| A290-8008-X107 | Power feed upper & lower 8 x 4 x 10 Fanuc | 2306330 |

| A290-8011-V352 | Break shoe upper Fanuc | 2456392 |

| A290-8011-X753 | Diamond guide upper & lower Ø 0,205 mm Fanuc | 2406120 |

| A290-8011-X754 | Diamond guide upper & lower Ø 0,255 mm Fanuc | 2406121 |

| A290-8011-X755 | Diamond guide upper & lower Ø 0,305 mm Fanuc | 2406122 |

| A290-8011-X833 | Diamond guide upper & lower Ø 0,205 mm Fanuc | 2406128 |

| A290-8011-X834 | Diamond guide upper & lower Ø 0,255 mm Fanuc | 2406131 |

| A290-8011-X835 | Diamond guide upper & lower Ø 0,305 mm Fanuc | 2406129 |

| A290-8018-X443 | Diamond guide lower Ø 0,205 mm AWF Fanuc | 2406103 |

| A290-8018-X444 | Diamond guide lower Ø 0,255 mm AWF Fanuc | 2406108 |

| A290-8018-X445 | Diamond guide lower Ø 0,305 mm AWF Fanuc | 2406105 |

| A290-8018-X463 | Diamond guide upper Ø 0,205 mm AWF Fanuc | 2406104 |

| A290-8018-X464 | Diamond guide upper Ø 0,255 mm AWF Fanuc | 2406109 |

| A290-8018-X465 | Diamond guide upper Ø 0,305 mm AWF Fanuc | 2406106 |

| A290-8021-X602 | Isolation plate upper 51 x 33 x 29 Fanuc | 2406220 |

| A290-8021-X709 | Isolation plate lower Fanuc | 2456001 |

| A290-8021-X765 | Diamond guide upper Ø 0,205 mm Fanuc | 2406100 |

| A290-8021-X766 | Diamond guide upper Ø 0,255 mm Fanuc | 2406101 |

| A290-8021-X767 | Diamond guide upper Ø 0,305 mm Fanuc | 2406102 |

| A290-8021-X775 | Diamond guide lower Ø 0,205 mm Fanuc | 2406110 |

| A290-8021-X776 | Diamond guide lower Ø 0,255 mm Fanuc | 2406111 |

| A290-8021-X777 | Diamond guide lower Ø 0,305 mm Fanuc | 2406112 |

| A290-8021-Y725 | Die Guide Support Matra/Fanuc | 2406011 |

| A290-8021-Y745 | Water nozzle upper & lower Ø 4,0 mm Fanuc 3 holes | 2467041 |

| A290-8021-Y745 | Water nozzle upper & lower Ø 5,5 mm Fanuc | 2467014 |

| A290-8021-Y755 | Water nozzle upper & lower Ø 4,0 mm Fanuc 1 hole | 2467043 |

| A290-8032-X735 | Diamond guide lower Ø 0,205 mm AWF Fanuc | 2406160 |

| A290-8032-X736 | Diamond guide lower Ø 0,255 mm AWF Fanuc | 2406162 |

| A290-8032-X737 | Diamond guide lower Ø 0,305 mm AWF Fanuc | 2406164 |

| A290-8032-X765 | Diamond guide lower Ø 0,205 mm Fanuc | 2406318 |

| A290-8032-X766 | Diamond guide lower Ø 0,255 mm Fanuc | 2406319 |

| A290-8032-X767 | Diamond guide lower Ø 0,305 mm Fanuc | 2406320 |

| A290-8032-Y611 | Water nozzle upper Ø 5,5 mm AWF Fanuc | 2467005 |

| A290-8032-Z882 | Power feed upper & lower 16 x 6,3 x 6 AWF Fanuc | 2306332 |

| A290-8037-X645 | Guide upper Ø 0,4 mm Fanuc | 2456103 |

| A290-8037-X692 | Isolation plate upper 51 x 31 x 30 Fanuc | 2406221 |

| A290-8037-X805 | Pinch Pulley Fanuc | 2467070 |

| A290-8037-X879 | Water nozzle lower Ø 5,5 mm AWF Fanuc | 2467003 |

| A290-8039-V352 | Break shoe upper Ø 100 x 22 mm Fanuc | 2406048 |

| A290-8048-X771 | Water nozzle upper Ø 7,0 mm Fanuc | 2467007 |

| A290-8048-X772 | Water nozzle lower Ø 7,0 mm Fanuc | 2467008 |

| A290-8048-Y771 | Water nozzle Fanuc | 2467026 |

| A290-8048-Y772 | Water nozzle Fanuc | 2467027 |

| A290-8092-X702 | Diamond guide upper Ø 0,105 mm AWF Fanuc | 2406210 |

| A290-8092-X704 | Diamond guide upper Ø 0,155 mm AWF Fanuc | 2406213 |

| A290-8092-X705 | Diamond guide upper Ø 0,205 mm AWF Fanuc | 2406216 |

| A290-8092-X706 | Diamond guide upper Ø 0,255 mm AWF Fanuc | 2406219 |

| A290-8092-X707 | Diamond guide upper Ø 0,305 mm AWF Fanuc | 2406222 |

| A290-8101-X312 | Isolation plate lower Ø 72 x 15 Fanuc | 2467964 |

| A290-8101-X371 | Break shoe upper Ø 140 x 22 mm Fanuc | 2456311 |

| A290-8101-X394 | Feed Guide Plastic 13 x 20 x 19 mm Fanuc | 2456214 |

| A290-8101-X394 | Feed Guide Ceramic 13 x 20 x 19 mm Fanuc | 2456224 |

| A290-8101-X509 | Isolation plate upper 40 x 40 x 34 Fanuc | 2406223 |

| A290-8101-X730 | Diamond guide upper Ø 0,105 mm Fanuc | 2467205 |

| A290-8101-X733 | Diamond guide upper Ø 0,205 mm Fanuc | 2406176 |

| A290-8101-X734 | Diamond guide upper Ø 0,255 mm Fanuc | 2406179 |

| A290-8101-X735 | Diamond guide upper Ø 0,305 mm Fanuc | 2406182 |

| A290-8101-X740 | Diamond guide lower Ø 0,105 mm Fanuc | 2467204 |

| A290-8101-X743 | Diamond guide lower Ø 0,205 mm Fanuc | 2406196 |

| A290-8101-X744 | Diamond guide lower Ø 0,255 mm Fanuc | 2406199 |

| A290-8101-X745 | Diamond guide lower Ø 0,305 mm Fanuc | 2406202 |

| A290-8101-X750 | Power feed upper & lower 2,8 x 7,7 x 23 Fanuc | 2306331 |

| A290-8101-X755 | Water nozzlen support holder lower Fanuc | 2467011 |

| A290-8101-X756 | Water nozzle lower Ø 6,5 mm Fanuc | 2467009 |

| A290-8101-X761 | Guide Base lower 75 x 56 x 66 Fanuc | 2467076 |

| A290-8101-X765 | Pulley lower Ceramic Ø 38 x 22 x 12 mm Fanuc | 2456308 |

| A290-8101-X774 | Water nozzle lower Ø 4,0 mm Fanuc | 2467104 |

| A290-8101-Z382 | Pinch Pulley Ceramic 40 x 20 x 18 mm Fanuc | 2306175 |

| A290-8101-Z383 | Feed Pulley Ceramic Ø 40 x 20 x 19 mm Fanuc | 2406045 |

| A290-8102-X393 | Feed Wire Guide Plastic 57 x 20 x 20 mm Fanuc | 2456324 |

| A290-8102-X620 | Guide upper Ø 0,5 mm AWF Fanuc | 2456104 |

| A290-8102-X622 | Pipe head Fanuc | 2467036 |

| A290-8102-X656 | Rubber chuck Fanuc | 2406500 |

| A290-8102-X657 | Cutting electrode Fanuc | 2406993 |

| A290-8102-X723 | Nozzle Base upper Ø58 x 19T AWF Fanuc | 2467030 |

| A290-8102-X727 | Platte Fanuc | 2306166 |

| A290-8102-X728 | Spring Fanuc | 2306146 |

| A290-8102-X751 | Water nozzle upper Ø 6,5 mm AWF Fanuc | 2467012 |

| A290-8102-X752 | Water nozzle upper Ø 12,0 mm AWF Fanuc | 2467017 |

| A290-8102-X763 | Block Fanuc | 2306159 |

| A290-8102-X764 | Jet Nozzle Ø 11 mm/6 x Ø 2.0 x 13H mm Fanuc | 2306158 |

| A290-8102-X771 | Water nozzle lower Ø 6,5 mm AWF Fanuc | 2467013 |

| A290-8102-X772 | Water nozzle lower Ø 12,0 mm AWF Fanuc | 2467018 |

| A290-8102-X774 | Water nozzle lower Ø 4,0 mm AWF Fanuc | 2467016 |

| A290-8102-X775 | Water nozzle upper Ø 4,0 mm AWF Fanuc | 2467015 |

| A290-8102-Y722 | Guide Base Alpha IA Fanuc | 2456124 |

| A290-8102-Y755 | Jet Nozzle Ceramic upper Ø 0,8 mm AWF Fanuc | 2456325 |

| A290-8102-Y756 | Jet Nozzle Ceramic upper Ø 1,5 mm AWF Fanuc | 2456312 |

| A290-8102-Y757 | Jet Nozzle Ceramic upper Ø 0,5 mm AWF Fanuc | 2456305 |

| A290-8102-Y761 | Jet nozzle Ø 1,0 mm | 2456330 |

| A290-8103-X705 | Diamond guide upper Ø 0,205 mm manual Fanuc | 2406181 |

| A290-8103-X707 | Diamond guide upper Ø 0,305 für 45° Konik Fanuc | 2406183 |

| A290-8103-X762 | Guide Base lower 40 x 40 x 25 Fanuc | 2467074 |

| A290-8103-X774 | Water nozzle lower Ø 2,0 mm Fanuc | 2467044 |

| A290-8104-X612 | Block Fanuc | 2307400 |

| A290-8104-X620 | Guide upper Ø 0,3 mm AWF Fanuc | 2456102 |

| A290-8104-X705 | Diamond guide upper Ø 0,205 mm AWF Fanuc | 2406185 |

| A290-8104-X706 | Diamond guide upper Ø 0,255 mm AWF Fanuc | 2406184 |

| A290-8104-X707 | Diamond guide upper Ø 0,305 mm AWF Fanuc | 2406186 |

| A290-8104-X774 | Water nozzle lower Ø 2,0 mm AWF Fanuc | 2467022 |

| A290-8104-X775 | Water nozzle upper Ø 2,0 mm AWF Fanuc | 2467023 |

| A290-8104-Y706 | Diamond guide finish cut upper 0,252 mm Fanuc | 2406295 |

| A290-8109-X776 | Water nozzle upper Ø 6,5 mm Fanuc | 2467039 |

| A290-8110(8092)-X715 | Diamond guide lower Ø 0,205 mm AWF Fanuc | 2406276 |

| A290-8110(8092)-X716 | Diamond guide lower Ø 0,255 mm AWF Fanuc | 2406279 |

| A290-8110(8092)-X717 | Diamond guide lower Ø 0,305 mm AWF Fanuc | 2406282 |

| A290-8110(8102)-Y726 | Guide upper Ø 1,0 mm AWF Fanuc | 2456106 |

| A290-8110-V384#STD | Pinch Pulley Ceramic Ø 40 x 28 x 30 mm Fanuc | 2456306 |

| A290-8110-V607#STD | Chuck MHZ J2 Fanuc | 2306342 |

| A290-8110-X317 | Bushing Fanuc | 2456123 |

| A290-8110-X382 | Pinch Pulley Ceramic Ø 40 x 28 x 30 mm Fanuc | 2456310 |

| A290-8110-X383 | Feed Pulley Ceramic Ø 40 x 12 x 30 mm Fanuc | 2456307 |

| A290-8110-X750 | Power feed upper & lower 4 x 12 x 23 Fanuc | 2306333 |

| A290-8110-X750 | Power feed upper & lower 4 x 12 x 30 Fanuc | 2306333L |

| A290-8110-X751 | Screw upper Fanuc | 2467985 |

| A290-8110-X752 | Screw lower Fanuc | 2467984 |

| A290-8110-X762 | Guide Base lower Ø 46 x 40 x 24.5 mm Fanuc | 2406036 |

| A290-8110-X770 | Guide block A lower 69 x 51 x 20 Fanuc | 2406503 |

| A290-8110-Y716 | Diamond guide finish cut lower Ø 0,252mm Fanuc | 2406296 |

| A290-8110-Y723 | Nozzle Base upper Fanuc | 2406964 |

| A290-8110-Y761 | Guide Base lower Fanuc | 2406026 |

| A290-8110-Y762 | Guide Base lower 46 x 40 x 23 mm Edelstahl Fanuc | 2467941 |

| A290-8110-Y767 | Base cover Fanuc lower | 2467940 |

| A290-8110-Y774 | Guide lower Ø 1,0 AWF Fanuc | 2456107 |

| A290-8110-Z715 | Diamond guide lower Ø 0,205 mm AWF Fanuc | 2406206 |

| A290-8110-Z716 | Diamond guide lower Ø 0,255 mm AWF Fanuc | 2406204 |

| A290-8110-Z717 | Diamond guide lower Ø 0,305 mm AWF Fanuc | 2406207 |

| A290-8111/09/01-X774 | Water nozzle upper Ø 4,0 mm Fanuc | 2467103 |

| A290-8111-X371 | Break shoe upper Ø 140 x 22 mm Fanuc | 2456390 |

| A290-8112-X382 | Pinch Pulley Ceramic Ø 80 x 22 mm Fanuc | 2456314 |

| A290-8112-X383 | Feed Pulley Ceramic Ø 80 x 22 mm Fanuc | 2456338 |

| A290-8112-X394 | Feed ceramic Guide Fanuc | 2406132 |

| A290-8112-X656 | Rubberchuck Fanuc | 2467970 |

| A290-8112-Z706 | Guide AWF Ø 0,25 mm 45° upper Fanuc | 2306322 |

| A290-8112-Z716 | Guide AWF Ø 0,25 mm 45° lower Fanuc | 2306323 |

| A290-8119-X382 | Pinch Pulley Fanuc | 2467947 |

| A290-8119-X383 | Drive Pulley Fanuc | 2467948 |

| A290-8119-X766 | Reverse Pulley ceramic Fanuc | 2456348 |

| A290-8119-X776 | Cover plate Fanuc | 2406015 |

| A290-8119-Y706 | Diamond guide finish cut lower 0,252 mm Fanuc | 2406291 |

| A290-8119-Y716 | DiamantdoppelGuide lower Ø 0,255 mm AWF Fanuc | 2406208 |

| A290-8119-Z780 | Power feed Fanuc | 2307705 |

| A290-8119-Z786 | Water nozzle lower Ø 4,0 mm AWF Fanuc | 2467038 |

| A290-8119-Z787 | Water nozzle lower Ø 6,5 mm Fanuc | 2467037 |

| A290-8119-Z788 | Water nozzle lower 12,0 mm Fanuc | 2467040 |

| A290-8119-Z791 | Water nozzle lower Ø 2,0 mm Fanuc | 24069101 |

| A60L-0001-0046#2.0 | Fuse Fanuc | 2306147 |

| A97L-0001-0664/15S1P | Power feed lower Ø25,4 x 9,5 mm Fanuc | 2306321 |

| A97L-0001-0670#1260Z | Bearing Fanuc | 2456200 |

| A97L-0001-0670#1450Z | Bearing Fanuc | 2456201 |

| A97L-0001-0670#DRF22 | Bearing lower Ø 25/22 x 8 x 7 mm Fanuc | 2456202 |

| A97L-0126-0001/15S1P | Power feed upper & lower 16 x 6 x 6,3 Fanuc | 2306310 |

| A97L-0201-0369/6001 | Bearing lower Ø 28 x 8 x 12 mm Fanuc | 2450211 |

| A97L-0201-0369-6203 | Bearing lower Ø 40 x 17 x 12 mm Fanuc | 2456401 |

| A97L-0201-0490#136 | Jet nozzle Fanuc | 2407003 |

| A97L-0201-0910#6003 | Bearing 35x17x10 mm closed Fanuc | 2456215 |

| A97L-0201-0911#6807 | Bearing Fanuc | 2456220 |

| A98L-0001-0465#2 | Grease Fanuc | 2456997 |

| A98L-0001-0972 | V-packing for 0C Fanuc | 2306191 |

| A98L-0001-0973 | V-Packing Fanuc | 2467991 |